The concept of a 360-VAC® excavator attachment is not new. However, our 360-VAC® was designed to incorporate a muti-stage filtration system which prevented dust and debris from entering the turbine and atmosphere whilst maintaining the power of a true VAC-EX unit.

Our 5-stage filtration system greatly reduces the operatives exposure to silica (crystalline silica) and other respirable inhalants from rail ballast and other materials encountered during excavation.

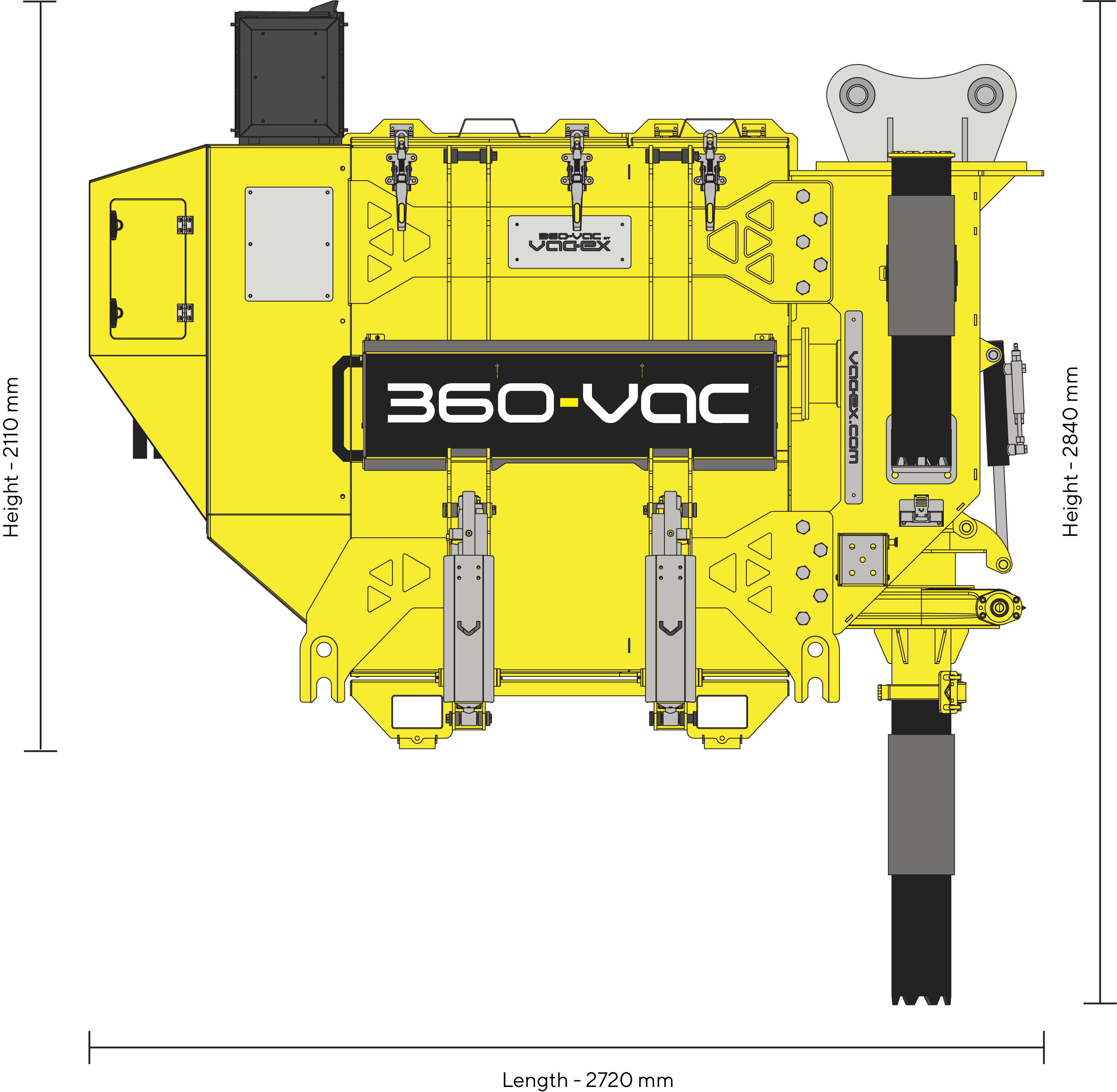

The 300 series 0.3m³ tank capacity prevents the 360-VAC® from being loaded-up beyond the smaller 360° excavator capabilities. Larger tanks are becoming available to accommodate these requirements, but will increase the overall width of the 360-VAC®.

Being mounted to an excavator arm gives multi-choice options for tipping:

- Dumpers

- Bulk bags

- Wagons

- Trailers

The debris doors are each operated by a pair of hydraulic cylinders which ensures a tight vacuum seal and precise opening which aids the excavated material to be deposited cleanly and precisely.

- 250 bar (3625 psi)

- 140 l/min (39 g/min)

Couldn’t be easier. The 360-VAC® design allows quick, almost dust free clean-off. The filters can also be quickly and easily removed for power washing.

Providing your excavator is able to safely operate the 360-VAC with a fully loaded skip and provide hydraulic flows and pressures close to the requirements, we can advise you further on hitch sizes and the hydraulic feed configurations. Generally, 360° excavators ranging from 14t are suitable.

360° only one feed, return and case drain? A fully proportional remote control is also available. This enables the operation of the 360-VAC® tank debris doors and hose rotator to be operated from the cab or by the operative - NO cabling is required between the R/C and 360-VAC.

The 360-VAC® is supplied as standard with a semi-flexible Vac pipe which allows the pipe end to cushion any misalignment during operation. This feature minimises any damage to both the unit and inground assets.

- Pin width and centres

- Welded or removeable pins,

Allows the 360-VAC® to rotate 180° around the headstock cradle. Improves versatility so you can work in narrow spaces without having to move the excavator.

As well as being able to lift and move the 360-VAC® on the cradle, it also features forklift pockets in the debris doors and 4x pin mounting points on the roof for overhead chain lifting.

The 360-VAC® significantly reduces the requirement for manual work using shovels and rakes in ballast and around services.

The company branding area doubles up as a working platform to enable the operatives to safely maintain

The 360-VAC® is supplied as standard with a semi-flexible Vac pipe which allows the pipe end to cushion any misalignment during operation. This feature minimises any damage to both the unit and inground assets.

The 360-VAC® is supplied as standard with a PE tipped Vac pipe. This provides a degree of insulation from electric shock hazards.

360° only one feed, return and case drain? A fully proportional remote control is also available. This enables the operation of the 360-VAC® tank debris doors and hose rotator to be operated from the cab or by the operative - NO cabling is required between the R/C and 360-VAC.

The industry leading tool for ground decompaction and clearance of spoil from underground assets. Powered from an external towed or vehicle mounted compressor.